About the event

Boosting the High-Tech sector with advanced production technologies

Join TU Delft for three dynamic Innovation Days, showcasing cutting-edge developments in automation, robotization, composite materials and manufacturing technologies.

This event features leading speakers, live demonstrations, and a rich agenda covering a wide range of topics, from academic insights to industry applications. It’s the perfect opportunity to exchange knowledge, explore new challenges, and connect with experts and partners in industry.

The aim: to shape the future of technology and innovation!

Participation is free of charge, but registration is required.

Day 1 - February 5

Symposium on robotics

Time: 09.00 - 17.30 hrs, including lunch and networking drinks

During this inspiring symposium we will explore how robotics is shaping the world around us. Leading experts and innovators will share groundbreaking advancements.

Get an insight on the growing impact of robotics on our daily lives! Dive into thought-provoking keynotes, poster presentations by PhD researchers and engaging panel discussions that bring together visionaries from academia, industry, and beyond.

This is your chance to connect, learn, and be inspired by the technologies driving societal change. Don’t miss this opportunity to see how robotics is transforming our future. Register now and be part of the conversation.

Please scroll down for day 2 and 3

Day 2 - February 6

Amazing robotic demos

Time: 12.30 - 15.00 hrs

Witness the groundbreaking advancements in robotics and join us for the official opening of our state-of-the-art Delft TapeLab.

Be amazed by live demonstrations of robotic systems developed within the NXTGEN Hightech projects. Explore the newest technologies in robotics, with applications in aerospace maintenance (MRO), aerospace manufacturing, and wind turbine blade manufacturing. Furthermore, you will have a unique insight in the latest developments in robotic software, control systems and inspection systems, highlighting how these innovations are shaping the future of these industries. Don’t miss this opportunity to see the future of Zero Defect Robotic Composites Manufacturing.

---------

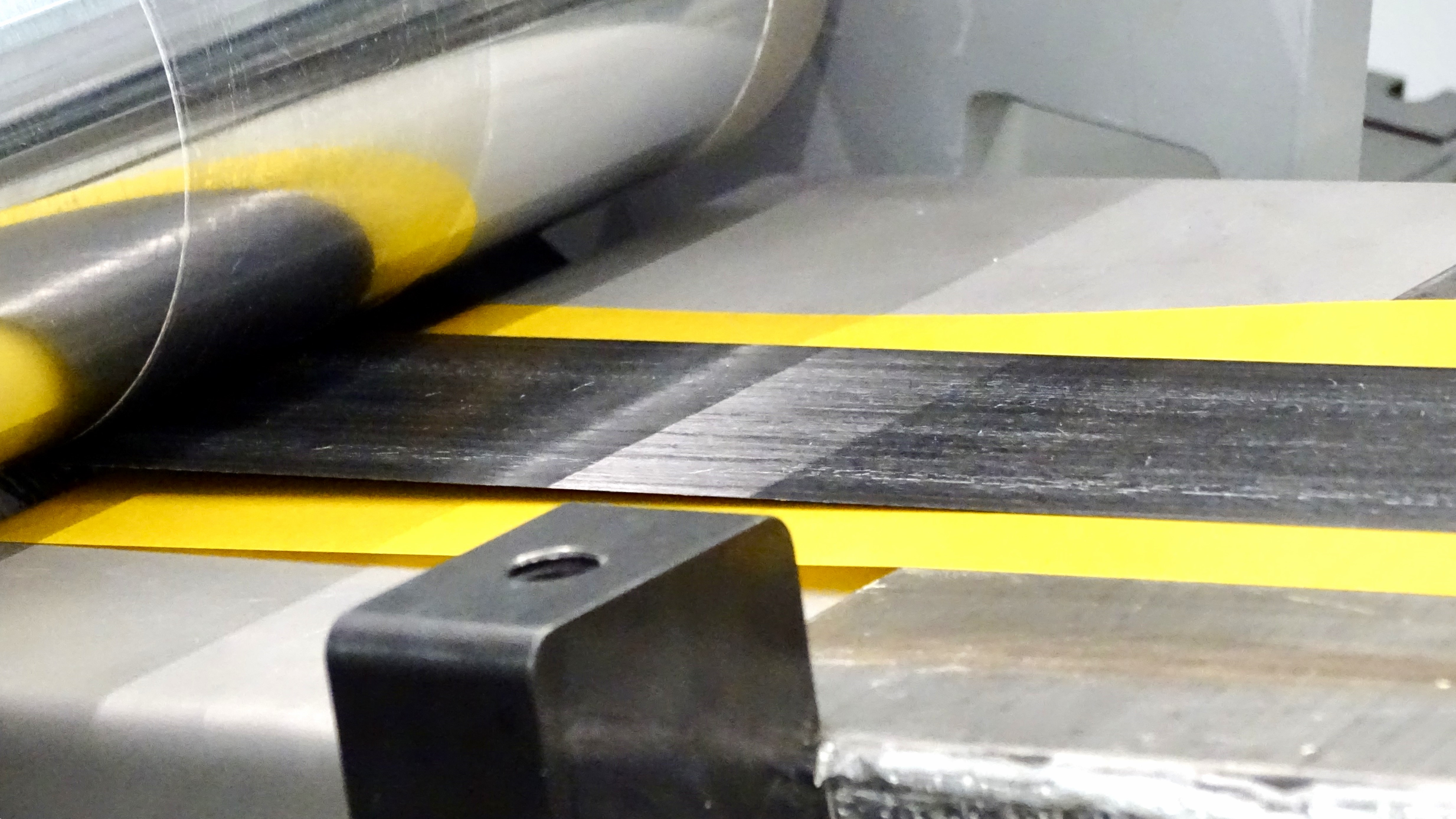

Opening Delft TapeLab

Time: 15.00 - 18.00 hrs, including networking drinks

Climate neutral aviation will be enabled by sustainable lightweight materials with unprecedented performance. In this scope, unidirectional composite materials represent a crucial keystone in architecting the most performing structures in tomorrow’s aircraft. How do we control all aspect of the microstructure of such materials? What is the effect of novel fibres and polymers? Will circular fibre sources replace those made of fossil sources? Can we control the properties through unconventional fibre architectures? How do I tailor unidirectional tapes to specific processes? These and many more question led to the creation of the Delft TapeLab, a one-of-its kind open research infrastructure for the manufacturing of unidirectional thermoplastic tapes.

A long-term investment of TU Delft, enabling research and technology development with societal impact, for the scientific community in the Netherlands and abroad.

Speakers include:

Henri Werij, Dean of the Faculty of Aerospace Engineering, TU Delft

Remko Akkerman, Professor, University of Twente, Thermoplastic Composites Research Center

Michael Hau, Sustainable Carbon Fibre Solutions

Martin Kampinga, Program Manager Sustainable Aviation, TU Delft

Rien van den Aker, Director, van Wees UD & Crossply technology

Baris Caglar, Assistant Professor, TU Delft

Cease the opportunity to discover how we contribute to sustainable aviation. Come to see yourself!

Please scroll down for day 3

Day 3 - February 7

Delft TapeLab Symposium

Time: 08.30 - 17.30 hrs, including lunch and networking drinks

Immerse yourself into the research ecosystem at the Delft Tapelab Symposium. This event brings together leading experts from academia and industry. Together, we will explore challenges and novel approaches to be addressed in the Delft TapeLab in the future.

Furthermore, an extensive poster presentation highlights the projects underway at TU Delft, addressing our approaches in novel composites towards a sustainable aviation.

Speakers include:

Opening: Clemens Dransfeld, TU Delft, Netherlands

Michael Wisnom, University of Bristol, United Kingdom - Opportunities for aligned thin-ply composites

Soraia Pimenta, Imperial College London, United Kingdom - The effect of real microstructures on the mechanics of fibre-composites

Joel Cugnoni, Haute École d'Ingénierie et de Gestion du Canton de Vaud, Switzerland - Thin-ply and hybrid composites: understanding micro-scale mechanisms to enable tailored composite properties

Luise Kärger, Karlsruhe Institute of Technology, Germany - Infiltration of continuous fibre-reinforced composites from micro to macro level

Mahoor Mehdikhani, Katholieke Universiteit Leuven, Belgium - What do we do with X-ray computed tomography images?

Judith Moosburger-Will, University of Augsburg, Germany - Fiber matrix interaction in carbon fiber reinforced epoxy resin

Remko Akkerman, University of Twente, Netherlands - When Details Matter - On the importance of microstructure in fibre composite materials

Arnt Offringa, GKN Aerospace, Netherlands - Development of lightweight composite technologies and products

Guillaume Ratouit, Toray Advanced Composites, Netherlands - Thermoplastic Prepregs technologies: from Fabric prepregs to Unidirectional tapes

Patrick Böhler, RWTH Aachen, ITA, Germany - Minimizing ATL Deposition Errors Through Predictive Modeling and Control of Tape Properties

Be part of the future of materials science and innovation. Register today and join the academic forefront.

About the organisers

The NXTGEN Hightech Composites 03 project offers significant opportunities for growing our Dutch robotic eco-system and be impactful to society. The consortium partners are determined to tackle novel challenges. Together, we will improve manufacturing robots and processes for composite manufacturing. NXTGEN partners TU Delft and SAM XL are proud to invite you to this dynamic event.

TU Delft

Delft University of Technology (TU Delft) is the leading European university in aerospace engineering. To conduct groundbreaking research and speed up radical innovations, we collaborate with researchers in other universities and experts from other knowledge institutes. Together with partners in industry, we conduct experiments in our laboratories, to subsequently validate and demonstrate the latest technologies in our fieldlabs.

SAM XL

As a manufacturing automation expertise centre, SAM XL forms a unique liaison between TU Delft faculties, the industry and suppliers. This fieldlab develops software and hardware to enhance the intelligence, connectivity and flexibility of industrial robots. The robot technology for executing complex and varied tasks on large structures is validated and demonstrated in our own industrial-scale automation lab. SAM XL also provides hands-on training for students and employers from industry , to uplift their digital skills in executing automation projects.

This event is powered by NXTGEN Hightech

TU Delft NXTGEN Innovation Days

Registration website for TU Delft NXTGEN Innovation Days

Registration website for TU Delft NXTGEN Innovation DaysTU Delft NXTGEN Innovation Dayscommunications-samxl@tudelft.nl

TU Delft NXTGEN Innovation Dayscommunications-samxl@tudelft.nlhttps://www.aanmelder.nl/tudnxtgeninnovationdays

2025-02-05

2025-02-07

OfflineEventAttendanceMode

EventScheduled

TU Delft NXTGEN Innovation DaysTU Delft NXTGEN Innovation Days0.00EUROnlineOnly2019-01-01T00:00:00Z

To be announcedTo be announced